James Hardie 4×8 panels offer a modern aesthetic and streamlined installation process for homeowners and professionals alike. Detailed installation guides, often available as a PDF, are crucial for success.

These fiber cement panels provide durability and require adherence to specific guidelines for optimal performance, as outlined in official documentation.

What are James Hardie 4×8 Panels?

James Hardie 4×8 panels represent a significant advancement in exterior siding technology, offering a durable and aesthetically pleasing alternative to traditional materials. These large-format panels, typically constructed from fiber cement, are designed for quicker and more efficient installation compared to individual planks.

The “4×8” designation refers to the panel’s dimensions – four feet wide and eight feet long – providing substantial coverage with each piece. Installation resources, frequently found as a downloadable PDF from the James Hardie website, detail the composition and specific properties of these panels. They are engineered to resist impacts, fire, and pests, while also mimicking the look of natural wood.

Understanding the panel’s construction and recommended handling procedures, as outlined in the PDF guide, is vital for a successful and long-lasting installation.

Benefits of Using Hardie Panels

James Hardie panels offer a compelling array of benefits for homeowners and builders. Their exceptional durability stands out, resisting rot, warping, and insect damage – issues common with traditional wood siding. The fire-resistant properties provide enhanced safety and peace of mind, often contributing to lower insurance premiums.

Furthermore, these panels require minimal maintenance, unlike wood which demands regular painting and staining. Detailed installation guides, readily available as a PDF, emphasize the long-term cost savings associated with Hardie’s longevity.

Aesthetically, Hardie panels offer versatile design options, and their consistent quality ensures a beautiful, uniform finish. The PDF documentation highlights the product’s ability to withstand various weather conditions, making it a reliable choice for diverse climates.

Preparing for Installation

Careful preparation is key for a successful Hardie panel project. Review the 4×8 installation PDF, gather necessary tools, and confirm local building codes before starting.

Tools and Materials Needed

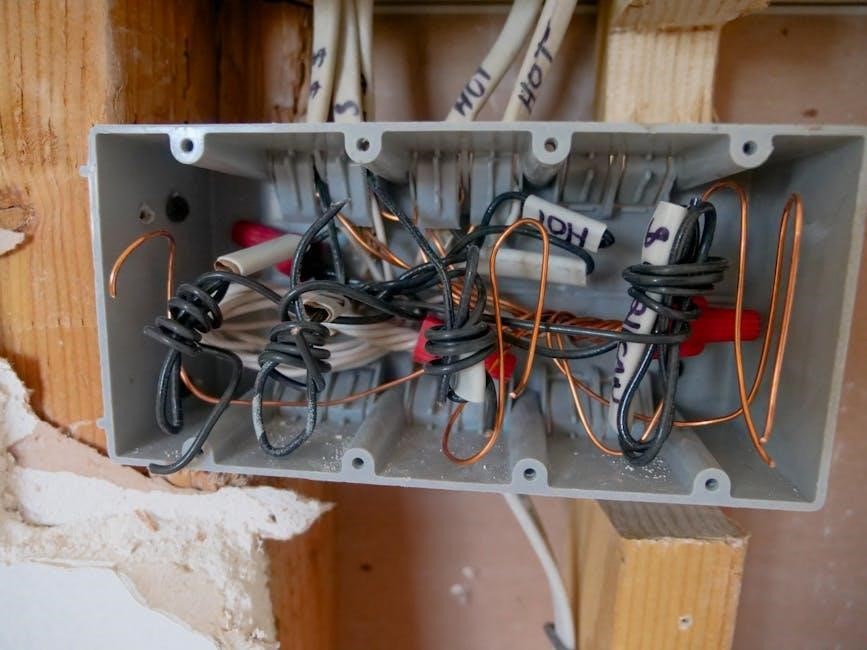

Successfully installing James Hardie 4×8 panels requires a specific set of tools and materials. The installation PDF details these comprehensively, but generally includes a circular saw with a fiber cement blade, a miter saw for precise cuts, and a pneumatic nailer designed for fiber cement siding.

Essential fasteners are specifically coated screws, ensuring corrosion resistance. You’ll also need a chalk line for accurate layout, a measuring tape, a level, safety glasses, and work gloves. Don’t forget appropriate caulk and sealant for seams and edges. A hammer, utility knife, and potentially scaffolding or a ladder are also vital, depending on the project’s height. Always refer to the official PDF for the most up-to-date and complete list.

Safety Precautions

Prioritizing safety during James Hardie 4×8 panel installation is paramount. The official installation PDF emphasizes wearing safety glasses to protect against fiber cement dust, which can irritate eyes and lungs. A dust mask or respirator is also crucial, especially when cutting the panels.

Work gloves protect hands from sharp edges, and sturdy footwear provides stability. When working at heights, utilize appropriate fall protection, such as harnesses and scaffolding. Be mindful of power tool safety, following manufacturer guidelines. Always disconnect power tools before changing blades or making adjustments. Proper ventilation is essential when cutting, and responsible dust disposal is vital. Refer to the PDF for detailed safety guidelines.

Understanding Building Codes and Permits

Before commencing any James Hardie 4×8 panel installation, thoroughly research local building codes and permit requirements. The installation PDF doesn’t cover these specifics, as they vary significantly by location. Contact your local building department to determine necessary permits for siding replacement or new construction.

Ensure your project adheres to fire-resistance regulations, wind load requirements, and any specific siding material stipulations. Compliance avoids potential fines and ensures structural integrity. The PDF highlights the importance of following all applicable laws. Ignoring these regulations can affect insurance coverage and resale value. Proper planning and adherence to codes are essential for a successful and legally compliant installation.

Installation Process: A Step-by-Step Guide

Refer to the 4×8 Hardie panel installation PDF for detailed instructions, starting with wall preparation, cutting, and secure fastening with appropriate screws.

Preparing the Wall Surface

Prior to Hardie panel installation, as detailed in the 4×8 Hardie panel installation PDF, ensure the wall surface is structurally sound and properly prepared. This involves verifying that the framing meets local building codes and is free from any rot or damage.

A weather-resistant barrier, like a house wrap, is essential for moisture management and should be installed correctly, overlapping seams according to manufacturer’s instructions. The wall must be flat and plumb to ensure proper panel alignment and a professional finish.

Remove any existing siding or debris, leaving a clean and stable surface. Addressing these foundational steps, as outlined in the PDF, will contribute significantly to a successful and long-lasting installation.

Cutting Hardie Panels

Cutting James Hardie panels requires specific techniques and tools, as detailed in the 4×8 Hardie panel installation PDF. Traditional wood-cutting tools are not recommended due to the fiber cement composition. Utilizing a fiber cement cutter or carbide-tipped saw blades is crucial for clean, precise cuts.

Always wear safety glasses and a dust mask to protect against silica dust generated during cutting. Score the panel before cutting to prevent chipping, and support the material adequately to avoid breakage.

The PDF emphasizes making accurate measurements and planning cuts to minimize waste. Remember to account for overlaps and seams when determining cut lengths, ensuring a professional and secure fit.

Initial Panel Placement and Fastening

Initial panel placement is critical for a successful 4×8 Hardie panel installation, as outlined in the official PDF guide. Begin by establishing a level starting point, typically at the bottom of the wall. Ensure the first panel is perfectly plumb and square before fastening.

The PDF stresses using appropriate corrosion-resistant fasteners, specifically designed for fiber cement. Pre-drilling is often recommended to prevent cracking. Fasteners should be driven flush with the panel surface, avoiding overdriving which can damage the material.

Maintain consistent spacing between fasteners, adhering to the guidelines in the PDF, to ensure proper panel support and weather resistance;

Proper Fastener Spacing and Placement

The 4×8 Hardie panel installation PDF details precise fastener specifications. Generally, fasteners should be placed 3/8 inch from panel edges, preventing crumbling and maintaining a clean aesthetic. Corner placement requires a minimum of 2 inches distance to avoid splitting.

Spacing between fasteners typically ranges from 12 to 16 inches vertically, depending on wind load requirements and local building codes, as detailed in the PDF. Staggering fasteners provides enhanced holding power and distributes stress evenly.

Always consult the PDF for specific recommendations based on panel thickness and substrate material. Incorrect spacing or placement can compromise the integrity of the installation.

Overlapping and Seaming Panels

The 4×8 Hardie panel installation PDF emphasizes proper overlapping and seaming techniques for weather resistance. Typically, a minimum overlap of 1 ½ inches is recommended at vertical joints, ensuring water runoff. Horizontal seams require careful attention to detail.

Staggering vertical seams creates a more robust and visually appealing installation. The PDF outlines the use of HardieBacker or similar materials to reinforce seams and prevent moisture intrusion. Proper sealing with high-quality caulk is also crucial.

Always refer to the PDF for specific guidance on seam treatments based on climate and exposure conditions, guaranteeing a long-lasting and watertight exterior.

Specific Installation Considerations

The 4×8 Hardie panel installation PDF details unique challenges around windows, doors, and corners, requiring precise cutting and sealing for a professional finish.

Installing Around Windows and Doors

Proper flashing is paramount when installing James Hardie panels around windows and doors, as detailed in the 4×8 Hardie panel installation PDF. This prevents water intrusion and maintains the integrity of the building envelope.

Carefully measure and cut the panels to create a snug fit, leaving a consistent reveal around the window or door frame. Utilize appropriate sealants, as recommended by James Hardie, to fill any gaps and create a watertight barrier.

The PDF emphasizes the importance of maintaining proper clearances to allow for expansion and contraction of both the siding and the window/door frame. Incorrect installation can lead to cracking or moisture damage, so meticulous attention to detail is essential.

Always refer to the manufacturer’s instructions for specific flashing and sealing requirements.

Dealing with Corners and Edges

The 4×8 Hardie panel installation PDF stresses the importance of precise cuts and proper detailing when addressing corners and edges. Utilizing corner posts or creating overlapping seams are common techniques for achieving a professional finish.

For outside corners, consider using pre-fabricated corner posts or carefully mitering the panels to create a seamless look. Inside corners often require a more nuanced approach, potentially involving backer boards and careful sealing.

Pay close attention to fastener placement near edges to avoid cracking or splitting the panels. The PDF provides guidance on appropriate fastener spacing and depth.

Caulking and sealing exposed edges are crucial for preventing moisture penetration and ensuring long-term durability. Always follow James Hardie’s recommendations for compatible sealants.

Vertical vs. Horizontal Installation

The 4×8 Hardie panel installation PDF details both vertical and horizontal installation methods, outlining the advantages and considerations for each. Horizontal installation mimics traditional siding, while vertical installation offers a more contemporary aesthetic.

Panel orientation impacts seam placement and water runoff; the PDF emphasizes proper lapping techniques regardless of the chosen direction. Vertical installation often requires more precise alignment to avoid a skewed appearance.

Fastener patterns differ based on orientation, with the PDF providing specific diagrams for optimal panel security. Consider the architectural style of your home when deciding between vertical and horizontal layouts.

Always prioritize proper flashing and weather barriers, as detailed in the documentation, to protect against moisture intrusion, irrespective of installation direction.

Finishing Touches & Important Notes

The 4×8 Hardie panel installation PDF stresses the importance of proper caulking, sealing, and painting for longevity. Following these final steps ensures a beautiful, durable finish.

Caulking and Sealing

According to the 4×8 Hardie panel installation PDF, meticulous caulking and sealing are paramount for a weather-tight and aesthetically pleasing result. Apply a high-quality, paintable exterior-grade caulk to all seams, joints, and around windows and doors.

Ensure the caulk is compatible with fiber cement siding to prevent any adverse reactions. Pay close attention to areas prone to water penetration, such as top edges of panels and corner intersections. Proper sealing prevents moisture intrusion, safeguarding the structure and extending the lifespan of the siding.

Backer rods should be used in larger gaps before caulking to ensure adequate sealant depth and adhesion. Regularly inspect caulked areas and reapply as needed to maintain a watertight barrier.

Painting and Finishing Options

The 4×8 Hardie panel installation PDF emphasizes the importance of proper surface preparation before painting. James Hardie recommends 100% acrylic latex paints specifically designed for fiber cement siding. Priming is crucial, utilizing a primer formulated for cementitious materials to ensure optimal adhesion and coverage.

Dark colors may require multiple coats and can affect the siding’s temperature, potentially impacting warranty coverage – consult the documentation. Light, reflective colors are often preferred for energy efficiency.

Avoid oil-based paints, as they can hinder moisture release. Follow the paint manufacturer’s instructions regarding application techniques and drying times for a durable, long-lasting finish.

James Hardie Installation Instructions – Importance

The 4×8 Hardie panel installation PDF repeatedly stresses that strict adherence to James Hardie’s written instructions is paramount. Deviating from these guidelines can void the warranty and compromise the siding’s performance, leading to issues like cracking, warping, or moisture damage.

Proper fastener spacing, overlap, and sealing techniques, detailed within the PDF, are critical for a weather-resistant and aesthetically pleasing installation. Ignoring these specifics can also violate local building codes.

James Hardie’s instructions aren’t merely suggestions; they are engineered requirements ensuring the siding system functions as designed, providing long-term durability and value.

Troubleshooting Common Issues

The 4×8 Hardie panel installation PDF addresses alignment, fastener problems, and weather-related challenges. Careful review of the document can resolve most installation hiccups.

Panel Alignment Problems

Addressing panel alignment issues during 4×8 Hardie panel installation is critical for a professional finish. The installation PDF emphasizes using a chalk line as a precise guide along the panel’s top edge before securing it.

Misalignment often stems from an uneven substrate, so ensuring a flat and level wall is paramount. If panels aren’t flush, double-check fastener placement – incorrect spacing can cause warping.

Minor adjustments can be made during installation, but significant discrepancies may require re-evaluation of the wall’s structure. The PDF also highlights the importance of checking for consistent reveals between panels, preventing visible gaps or overlaps. Consistent monitoring throughout the process minimizes these issues.

Fastener Issues

Proper fastening is paramount during 4×8 Hardie panel installation, and the official installation PDF details specific requirements. Using incorrect fasteners voids warranties and compromises structural integrity. The PDF stresses utilizing corrosion-resistant screws designed for fiber cement.

Common issues include driving fasteners too close to panel edges (minimum 3/8 inch) or corners (minimum 2 inches), leading to cracking. Under-driving or over-driving fasteners also creates problems.

Ensure consistent fastener depth and spacing as outlined in the documentation. If encountering resistance, pre-drilling may be necessary. Always refer to the PDF for approved fastener types and patterns to avoid costly rework and maintain the panel’s longevity.

Dealing with Weather Conditions During Installation

The 4×8 Hardie panel installation PDF explicitly addresses weather considerations. Avoid installation during freezing temperatures or when the panels are wet, as this can affect adhesion and create expansion/contraction issues.

Strong winds pose a challenge; secure panels immediately after placement. Rain can compromise cuts and sealant applications, so protect exposed edges.

Direct sunlight can accelerate sealant drying, impacting its effectiveness. The PDF recommends working in shaded areas or adjusting application times. Always check the forecast and prioritize safety; postpone installation if severe weather is predicted. Proper preparation and adherence to the PDF’s guidelines are crucial for a weather-resistant installation.

Resources and Further Information

James Hardie’s official website provides comprehensive resources, including a downloadable 4×8 panel installation PDF, videos, and CAD drawings for project planning.

Access detailed technical documentation to ensure a successful and compliant installation.

James Hardie Official Website & Documentation

James Hardie’s official website (jameshardie.com) serves as the primary hub for all things related to their fiber cement siding products, including the 4×8 panels. You’ll find a dedicated section for product information, specifications, and crucially, downloadable installation guides in PDF format.

These PDF documents are incredibly detailed, covering everything from pre-installation preparation to fastening schedules and finishing techniques. They are essential reading before commencing any project. The website also hosts technical bulletins addressing specific installation scenarios and frequently asked questions.

Furthermore, James Hardie provides access to building code compliance information and warranty details. Always refer to the latest version of the installation instructions, as guidelines can be updated to reflect best practices and evolving building standards. Proper adherence to these documents is vital for a successful and warrantied installation.

Finding Installation Videos and Guides

Beyond the official James Hardie website and its downloadable PDF installation guides, numerous online resources offer visual learning aids. Platforms like YouTube host channels – such as “Oldguydoingthings” – featuring step-by-step videos demonstrating Hardie panel installation techniques. These videos often complement the PDF instructions, providing a practical demonstration of the process.

Siding Simulator also offers real-world POV siding installation videos. Searching for “HardiePanel Vertical Siding installation” will yield a wealth of tutorials. Remember to verify the source and ensure the information aligns with the latest James Hardie guidelines.

Many professional contractors also create and share their own guides and videos, offering valuable insights and tips. Always prioritize official documentation, but these supplemental resources can enhance your understanding.